Research

The Separation Challenge

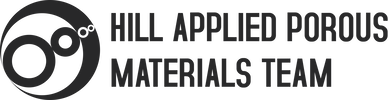

Separation processes currently use around 14 % of the USA energy consumption annually. This is necessary to obtain pure materials from natural resources in industry. We aim to reduce the energy and time costs of some separations and create new separations not previously possible. Our research team broadly aims at using porous materials to separate target molecules or ions. For this, we have utilised polymers, polymer-based materials and permanently porous nanomaterials to create designer composites.

These composites are then used in our research fields:

Separation processes currently use around 14 % of the USA energy consumption annually. This is necessary to obtain pure materials from natural resources in industry. We aim to reduce the energy and time costs of some separations and create new separations not previously possible. Our research team broadly aims at using porous materials to separate target molecules or ions. For this, we have utilised polymers, polymer-based materials and permanently porous nanomaterials to create designer composites.

These composites are then used in our research fields:

- Fundamental membrane research (anti-ageing membranes, chemically and thermally resistant membranes)

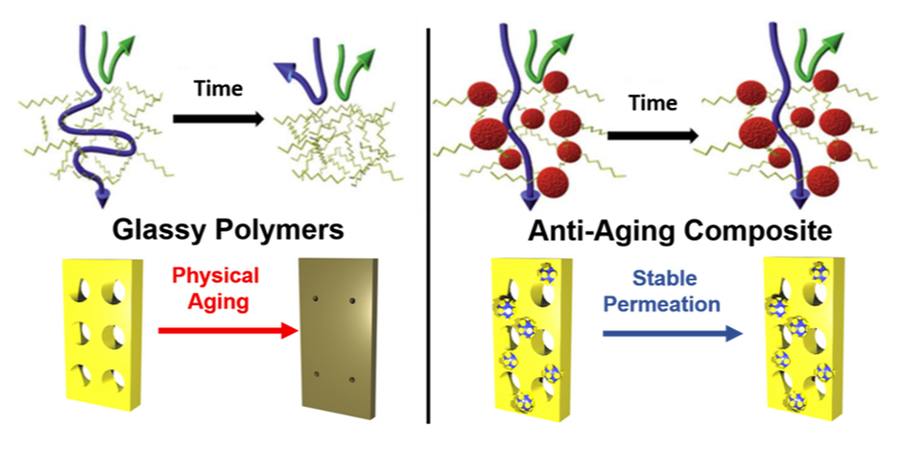

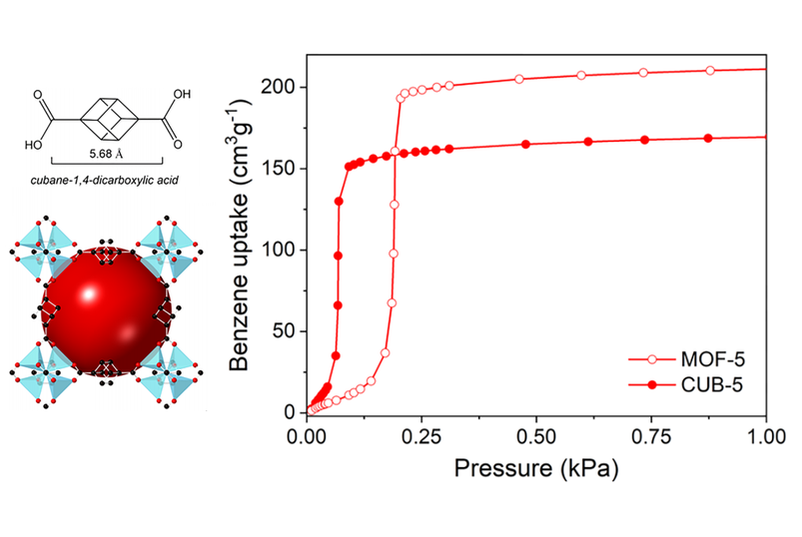

- Gas separations (direct air CO2 capture, oxygen capture and release, porous liquids)

- Liquid separations (desalination, lithium extraction, liquid organic hydrogen carrier separations)

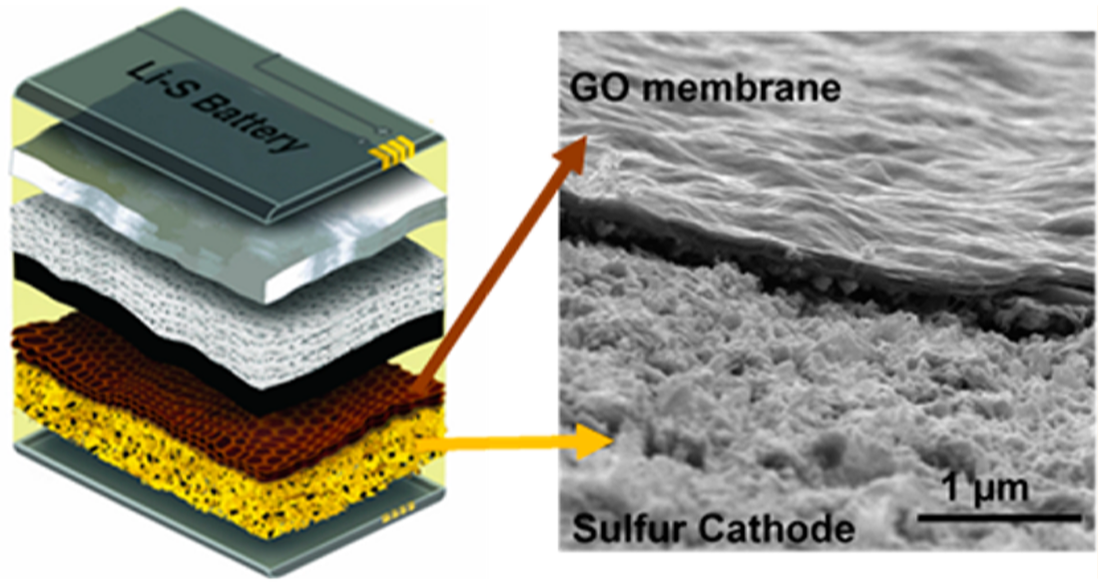

- Energy applications (lithium sulfur battery design)

- Biological applications (thermally tolerant drug encapsualtion, bioremediation)

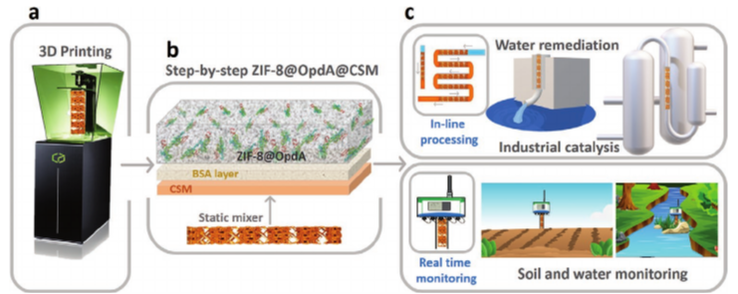

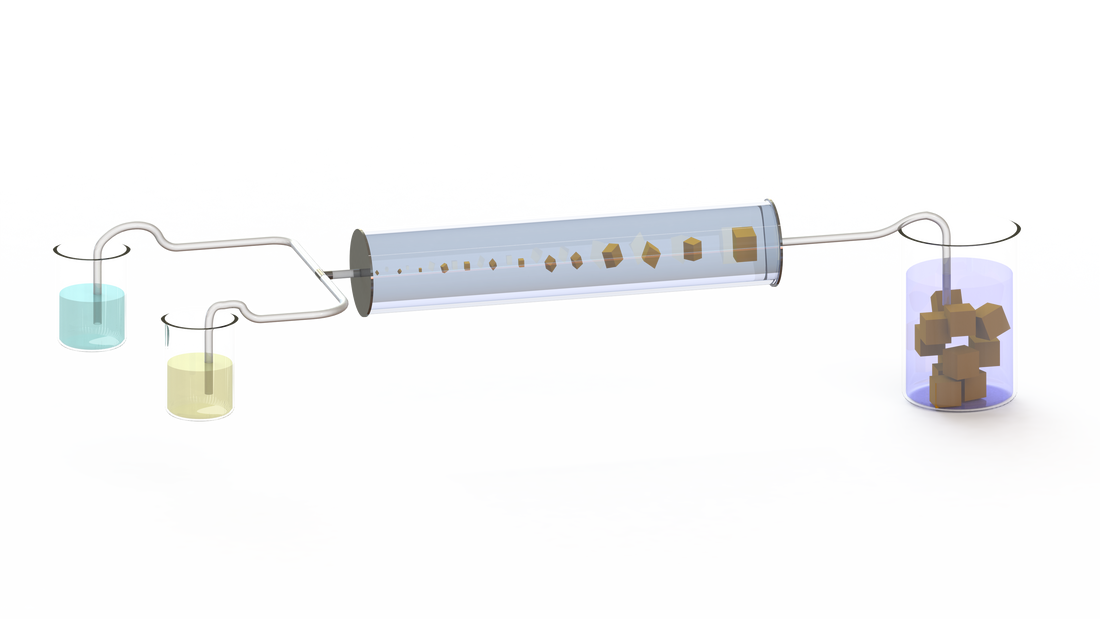

- Upscaling (flow chemistry, systems integration)